Technical Specifications:

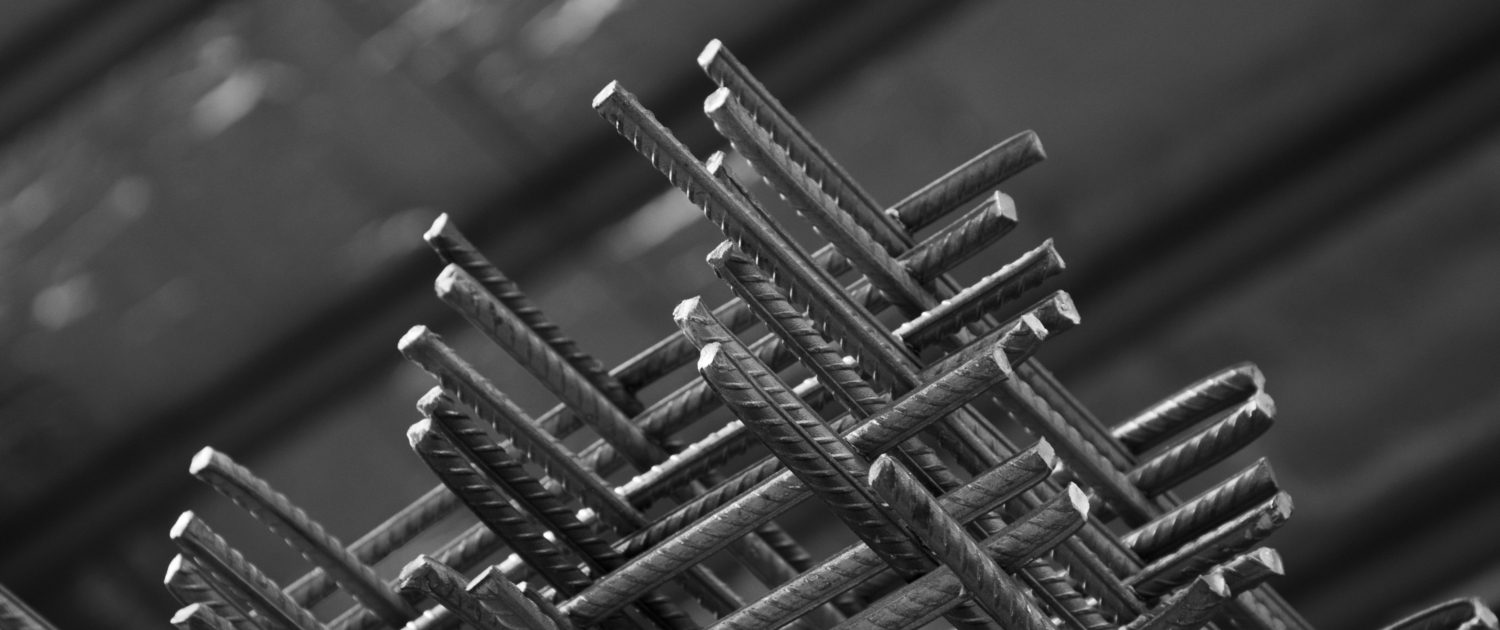

1. Longitudinal and transverse wire rods from 2 mm to 14 mm with grades of 1006, 1008, and 1010 in simple wire rode as well as A3 and A2 in a variety of ribbed round bars using Resistance Welding Method.

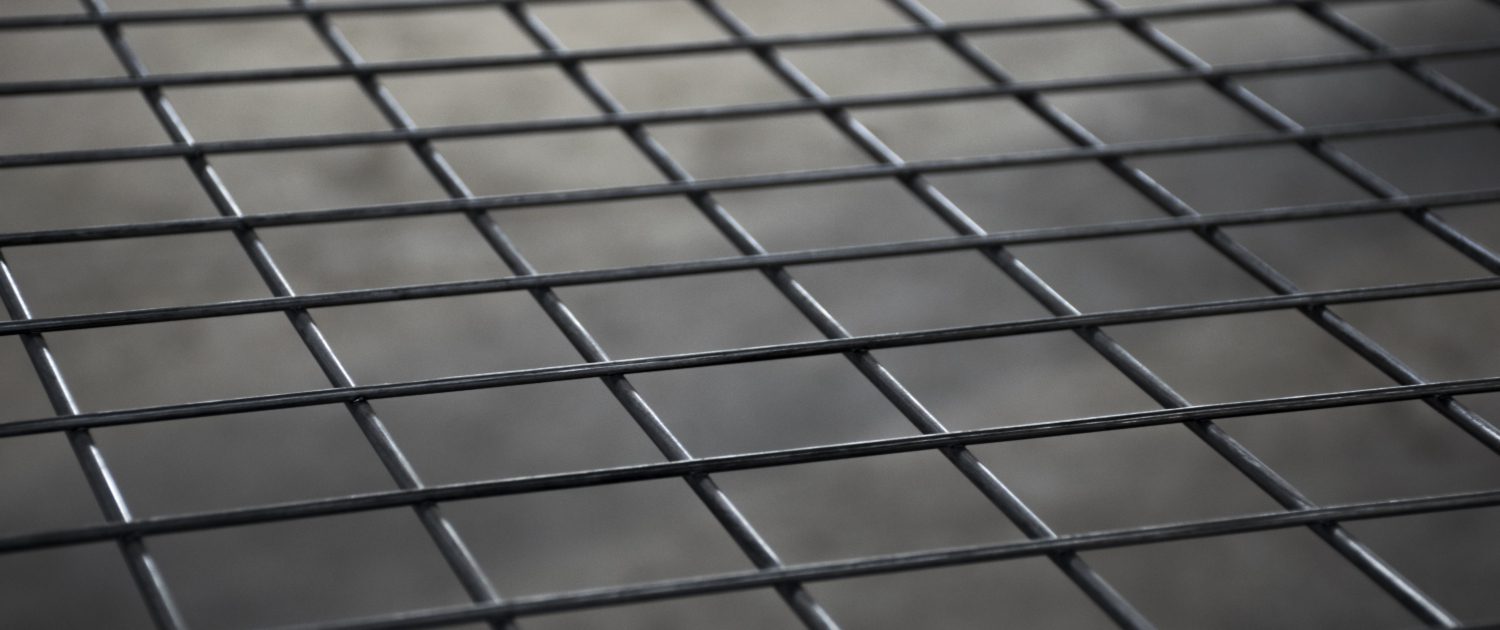

2. This production can be supplied in sheet size up to 2.5 m width and 6 meters length and with the squares and rectangular panels.

Components

- Digging and Nailing of Projects

- Concrete structures in tunnel form

- Steel or composite decks

- concrete prefabricated components

Applications

5. Subways, tunnels, and shelters

6. Flooring of Industrial halls, sports arena, niches, airports, highways and gas stations,

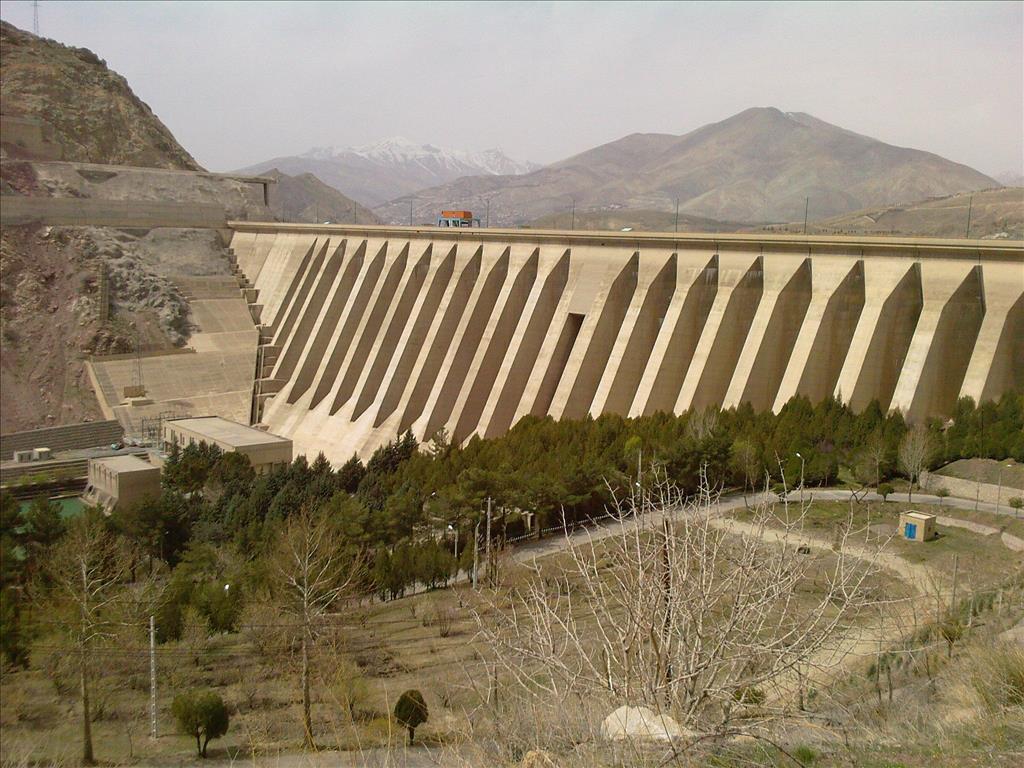

7. Construction of the dam, silo, bridge, pool, and water channels

Advantages of Steel bar welded mesh panels

- Saving in wire rod consumption due to the regularity of the panel’s distances and the same resistance welding at each node instead of manual welding

- The correct timing of projects due to the ease and speed of transportation and installation, in comparison with other wire rods placing methods

- More strength and security during earthquakes due to the bonding of steel and concrete mesh networks. 4. Significant reduction of soft annealed wire rods.

1 – Longitudinal and transverse wire rods from 2 mm to 14 mm with grades of 1006, 1008, and 1010 in simple wire rode as well as A3 and A2 in a variety of ribbed round bars using Resistance Welding Method.